Mechanical laboratory

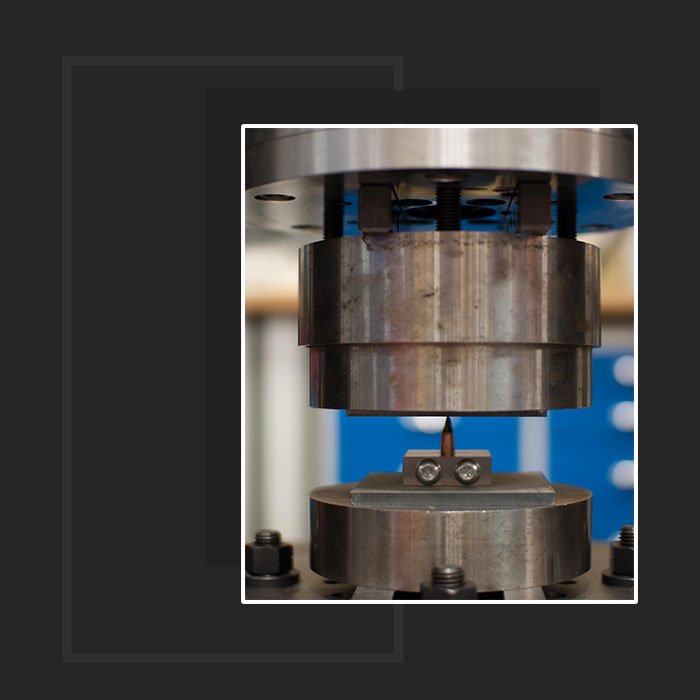

Tensile test

Tensile test (engineering tensile test); to demonstrate basic information about the strength of the material and to use as a test to accept the properties of the substance. In a tensile test, a single-dimensional tensile force is continuously increased, while the relative elongation is observed simultaneously.

The shape and size of the stress-strain curves of each metal depend on the chemical composition, thermal operation, previous history, deformation of the momson and strain rate, temperature, and tensile stress during the test. Tensile strength, suction strength, relative lengthening length and cross-sectional reduction are parameters that are used to describe the stress-strain curve of each metal. The first two parameters represent the strength and the two other criteria are the reciprocal of the formulation.

Impact test

Different types of shock tests are used to determine the tendency of the material to have a crisp or flaky behavior. This type of test reveals differences between materials that are not visible in the tensile test. There are two standard sample groups for the impact test with a groove: 1) a charpy sample with a square cross-sectional shape and a 45-degree or U-shaped groove horizontally arranged. 2) Isodate sample with a square or circular cross-section and a pivot groove which is vertically positioned.

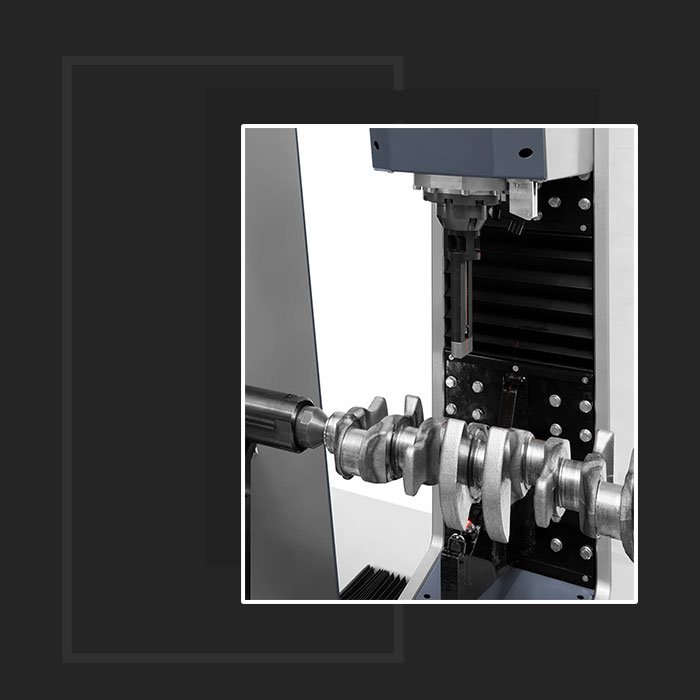

Bending test

The curvature or bending test is one of the simplest tests and is usually used for harsh materials that have linear elastic behavior.

There are two main types of bending tests, called three-point and four-point bending tests.

Surface roughness

Roughness is a measure of the surface texture and is determined by determining the vertical variation of the surface relative to the actual surface. If the changes are high, the surface is rough, and if it is small, it is flat. This quantity plays an important role in determining the interaction of objects, and knowing that many mechanical behavior behaviors are predictable.

Mechanical laboratory tests

| Test type | Test standard |

|---|---|

| Tensile test | BS EN ISO898, BS EN ISO6892, ASTM A370, ASTM B557M, ASTM E8/E8M, ASTM F606M, JIS Z2241, BS EN ISO4136 |

| Bending test | ANSI/AWS D1.1/D1.1M, API 1104, ASME SECTION IX, ASTM A370, ASTM E190, ASTM E290, JIS Z2248, BS EN 1SO5173 |

| Bargue test (bolts and nuts) | ASTM F738M, ASTM A194/A194M, ASTM F606M, ASTM F836M, ISO 898-1 |

| Health Check | ISO 898 |

| Health Check | ISO 898 |

| WEDGE test | BS EN ISO898-1, ASTM A370 |

| Hydrostatic and Pneumatic Pressure Test | ASME B1634 |

| Rebound Test (Reed Reed) | ISIRI 3132 |

| Flattening test | DIN EN ISO8492, ASTM A450, ASTM A1016 |

| FLANGE test | ASTM A450, ASTM A1016 |

| Determine surface fineness | DIN EN ISO 4288, DIN EN ISO4287 |

Our customers

Amir Kabir's Precision Measurement Laboratory as the reference for performing metallurgical-related tests in accordance with the scope of application.