Metallurgical Laboratory

The Metallurgical Laboratory aims to provide laboratory services to manufacturers, inspectors, and experts in automotive parts and equipment with the most advanced machines. The lab has certified 17025 ISO and has been able to conduct professional tests (PROFICIENY TEST) with reputable European laboratories in Different fields (hardness of all scales, shock absorption, analysis, elasticity and metagraphy) increase the quality level of tests.

Feasible tests

- Metal Hardening in All Brinell, Rockwell, and Vickersnow

- Metallography and structure analysis with optical and electrical microscopes including: austenite and ferrite grain size, determination of impurity number, measurement, and depth of hardness and dextrose ...

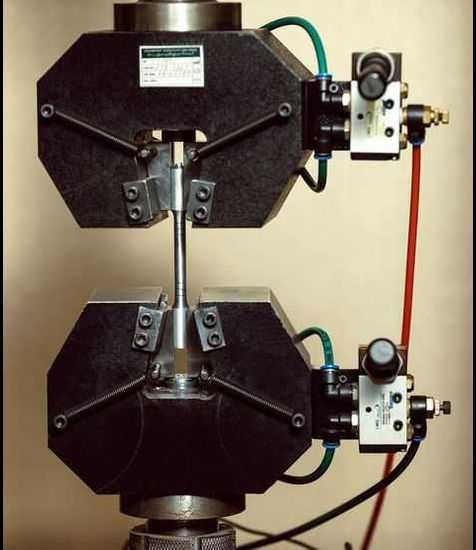

- mechanical properties tests of stretch and impact shawls

- Checking the quality and thickness of the various coatings

- Analysis of the causes of fracture failure (by examining the failure rate by stereo microscope and SEM)

- Non-destructive tests include Eddy Carnet, ultrasonic, magnetic particles and penetrating fluids on iron and non-ferrous parts.

- Carry out research tests such as reciprocating wear and dust pins and heat treatment with furnaces in various cooling environments for water, oil, and air.

- Quantum analysis of base alloys of iron, aluminum, copper and zinc.

Ultrasonic tests of Eddy Carnet Magnetic Particles are carried out by qualified personnel holding a LEVEL II certificate.